A contactor in an HVAC unit might fail due to electrical issues or wear and tear. Over time, components can degrade, causing malfunctions.

HVAC units rely on contactors to control the flow of electricity to the system’s components. These devices are essential for the proper functioning of heating and cooling systems. Electrical issues, such as short circuits or power surges, can damage contactors.

Wear and tear from frequent use can also lead to contactor failure. Routine maintenance and inspections can help identify potential problems early. Replacing worn-out contactors promptly ensures the HVAC unit operates efficiently. Understanding the common causes of contactor failure can prevent costly repairs and downtime, keeping your home comfortable year-round.

Introduction To Hvac System Reliability

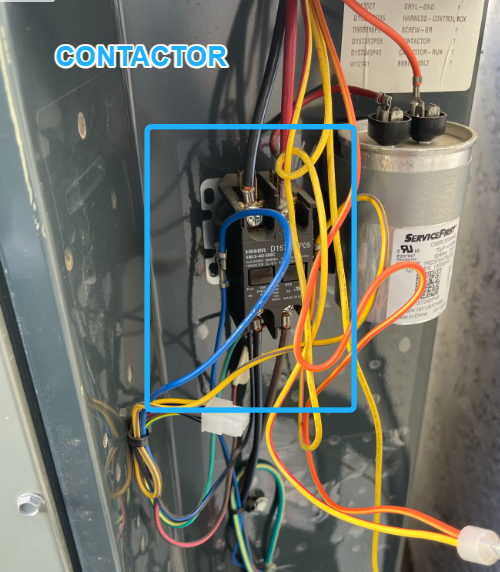

An HVAC system is essential for home comfort. It keeps the temperature just right. But for it to work well, every part must be reliable. The system has many components. One important part is the contactor.

The Role Of A Contactor

The contactor is like a switch. It controls the flow of electricity. When you turn on the HVAC, the contactor closes. This allows power to flow to the compressor and fan. Without it, the system can’t work. It’s a small part, but very important.

Signs Of Potential Failure

- Strange noises: Clicking or buzzing sounds can be a bad sign.

- System not starting: If the HVAC won’t turn on, the contactor might be the problem.

- Burned smell: A burnt smell can mean the contactor is overheating.

- Frequent cycling: If the system turns on and off a lot, the contactor could be failing.

| Sign | Possible Cause |

|---|---|

| Strange noises | Contact points are worn out. |

| System not starting | Contactor might be stuck open. |

| Burned smell | Contact points are overheating. |

| Frequent cycling | Contactor may not stay closed. |

Always check these signs. If you see any, call a professional. A small problem can become big if ignored.

Credit: reliablestandard.com

Common Causes Of Contactor Failure

An HVAC system’s contactor is vital for its operation. But, contactors can fail. Understanding common causes of contactor failure helps in maintaining HVAC units.

Electrical Overloads

Electrical overloads are a primary cause of contactor failure. When there’s too much current, the contactor can overheat. This leads to damage.

Causes of electrical overloads:

- Short circuits

- Excessive power draw

- Faulty wiring

Pitting And Arcing

Contactors experience pitting and arcing due to regular use. When contacts open or close, tiny sparks can form. This is called arcing.

Arcing damages the contact surfaces. Over time, this causes pitting. Pitted contacts have poor connectivity. This leads to contactor failure.

Common signs of pitting and arcing:

- Burn marks on contacts

- Irregular operation

- Unusual noises

Mechanical Wear And Tear

Mechanical wear and tear happens over time. Moving parts in the contactor can wear out. This includes springs, levers, and other components.

Factors causing mechanical wear:

- Frequent cycling

- Environmental conditions

- Age of the contactor

Regular maintenance can help reduce wear and tear. Replacing worn parts extends the life of the contactor.

Environmental Factors Affecting Contactor Lifespan

The lifespan of an HVAC contactor can be influenced by various environmental factors. These factors can cause early failure and affect the efficiency of the HVAC system. Understanding these elements can help in maintaining the longevity of your contactor.

Dust And Debris

Dust and debris can accumulate inside the HVAC unit. This accumulation can block the contactor and disrupt its operation. Over time, the contactor may overheat due to blocked airflow. This can lead to wear and tear, reducing its lifespan.

Corrosive Chemicals

Corrosive chemicals in the environment can damage the contactor. Such chemicals can come from cleaning agents or industrial emissions. Exposure to these chemicals can corrode the metal parts of the contactor. Corrosion can cause electrical faults and mechanical failures.

Temperature Extremes

Temperature extremes can also affect the contactor’s lifespan. High temperatures can cause the contactor to overheat. Overheating can lead to insulation breakdown and electrical failures. On the other hand, very low temperatures can make the metal parts brittle. Brittle parts can break easily, causing the contactor to fail.

| Environmental Factor | Effect on Contactor |

|---|---|

| Dust and Debris | Blocks airflow, causes overheating |

| Corrosive Chemicals | Corrodes metal parts, causes faults |

| Temperature Extremes | Causes overheating or brittleness |

Regular maintenance and proper placement of the HVAC unit can mitigate these environmental impacts. Keep the unit clean and away from harmful chemicals. Ensure it operates within a safe temperature range to prolong the contactor’s life.

Electrical Issues Leading To Failure

Electrical issues are a common reason for a contractor in an HVAC unit to fail. These problems can cause serious damage if left unchecked. Understanding these issues can help in preventing unit failure.

Voltage Irregularities

Voltage irregularities can significantly impact the performance of an HVAC unit. High or low voltage can cause the contractor to overheat or fail. This is because the contractor relies on a steady flow of electricity to function properly.

Table showing the impact of voltage irregularities:

| Voltage Level | Impact on Contractor |

|---|---|

| High Voltage | Overheating and potential failure |

| Low Voltage | Insufficient power, leading to poor performance |

Loose Connections

Loose connections are another common cause of contractor failure. When wires are not securely connected, they can create sparks or heat. This can lead to short circuits or complete failure of the unit.

Signs of loose connections:

- Sparks near connection points

- Intermittent operation of the unit

- Burn marks on wires or terminals

Faulty Capacitors

Faulty capacitors can also lead to contractor failure. Capacitors store electrical energy and release it when needed. If a capacitor is faulty, it can provide incorrect amounts of energy. This can cause the contractor to malfunction.

Common symptoms of faulty capacitors:

- Humming sound from the unit

- Failure to start or frequent shutdowns

- Visible bulging or leaking from the capacitor

Maintenance Mistakes And Oversights

Maintenance mistakes and oversights can lead to a failing contactor in an HVAC unit. Simple errors can cause major problems. Regular checks and proper care are crucial. Let’s explore some common issues.

Inadequate Inspections

Inadequate inspections can miss early signs of failure. Dirt and debris can build up. This can block the contactor and cause it to fail. Regular inspections help spot these issues early.

Delayed Replacements

Old parts need timely replacements. Delayed replacements can lead to wear and tear. This stress can cause the contactor to fail. Always replace parts as recommended.

Improper Installations

Improper installations can cause many problems. Loose connections can lead to electrical issues. This can damage the contactor. Make sure a professional installs the HVAC unit.

| Maintenance Task | Potential Issue |

|---|---|

| Inadequate Inspections | Dirt and debris buildup |

| Delayed Replacements | Wear and tear |

| Improper Installations | Loose connections |

Following these maintenance tips can prevent contactor failures. Regular checks, timely replacements, and proper installations are key. Keep your HVAC unit in top shape.

The Impact Of Hvac System Design

HVAC systems are complex. Their design impacts their efficiency and lifespan. Poor design can cause many issues, especially with the contractor. Understanding how design affects the contractor helps prevent failures.

Mismatched Components

Mismatched parts can lead to contractor failure. Each part in an HVAC system must be compatible. If not, the system works harder. This extra strain can cause the contractor to fail.

- Different brands may not work well together.

- Old and new parts should not mix.

- Check compatibility before installing parts.

Undersized Units

Undersized units struggle to meet demand. This puts extra stress on the contractor. The system runs longer and more often. This wears out the contractor faster.

| Unit Size | Impact on Contractor |

|---|---|

| Proper Size | Normal Wear |

| Undersized | Excessive Wear |

Over-cycling Problems

Frequent on-off cycles harm the contractor. Over-cycling happens in poorly designed systems. Each cycle heats and cools the contractor’s parts. This causes them to wear out quickly.

- Short cycles increase wear.

- Long cycles reduce strain.

Ensure your system is designed to minimize cycles.

Steps To Prevent Contactor Failure

Preventing contactor failure in an HVAC unit requires proactive steps. These steps can help ensure the longevity and efficiency of your HVAC system. Regular maintenance, upgrading components, and professional inspections are crucial.

Regular Maintenance

Regular maintenance is vital for an HVAC system’s health. Clean the unit’s coils and filters frequently. Dust and debris can cause the contactor to overheat. An overheated contactor may fail prematurely. Lubricate moving parts to reduce friction and wear. Check electrical connections for signs of wear or damage.

- Clean coils and filters

- Lubricate moving parts

- Inspect electrical connections

Upgrading Components

Upgrading components can prevent contactor failure. Use high-quality contactors with better materials. Enhanced materials withstand heat and stress better. Upgrade to a contactor with a higher current rating. A higher rating ensures it can handle power surges. Consider smart contactors for more precise control.

| Component | Benefit |

|---|---|

| High-Quality Contactors | Withstand heat and stress |

| Higher Current Rating | Handle power surges |

| Smart Contactors | Provide precise control |

Professional Inspections

Professional inspections are essential for preventing contactor failure. HVAC professionals can identify potential issues early. They can test the system’s performance and efficiency. Professionals can replace worn-out components before they fail. An annual inspection ensures your system runs smoothly.

- Identify potential issues early

- Test system performance

- Replace worn-out components

- Ensure smooth operation

Credit: www.youtube.com

Dealing With Contactor Failure

Experiencing a failure in your HVAC unit can be frustrating. A common issue is contactor failure. This component is crucial in managing the flow of electricity. Understanding how to deal with it can save time and money.

Troubleshooting Tips

- Check for loose wires: Loose wires can cause the contactor to fail. Inspect and tighten any loose connections.

- Inspect for debris: Dust and debris can interfere with the contactor’s function. Clean the contactor carefully.

- Test the coil: Use a multimeter to check if the coil has continuity. A lack of continuity indicates a problem.

- Look for visual signs: Burn marks or melting are clear signs of failure. Replace the contactor if you see these signs.

When To Call A Professional

Sometimes, troubleshooting isn’t enough. Here are signs that you need a professional:

- Repeated failures: If the contactor fails again after fixing, call an expert.

- Complex wiring: If the wiring seems complex, a professional can handle it safely.

- No improvement: If your unit doesn’t work after troubleshooting, seek expert help.

Cost Considerations

Understanding the costs involved can help you make informed decisions.

| Service | Average Cost |

|---|---|

| DIY Replacement | $20 – $50 |

| Professional Repair | $100 – $250 |

| Full Unit Inspection | $150 – $300 |

Choosing between DIY and professional help depends on your comfort level. Weigh the costs and benefits before deciding.

Future Of Hvac Contactors

The future of HVAC contactors is an exciting field. Innovations are making systems smarter and more efficient. These advancements promise fewer failures and better performance.

Smart Contactors

Smart contactors are transforming HVAC systems. They offer real-time monitoring and diagnostics. This helps identify issues before they become problems. Smart contactors also allow remote control, improving convenience.

Advancements In Materials

New materials are making HVAC contactors more reliable. Modern alloys resist wear and tear better. Improved insulation materials prevent short circuits. These advancements lead to longer-lasting contactors.

Predictive Maintenance

Predictive maintenance uses data to foresee failures. Sensors collect information about contactor performance. This data is analyzed to predict issues. Fixing problems before they occur saves time and money.

Credit: www.reddit.com

Conclusion

Understanding why a contactor in an HVAC unit fails is crucial for maintaining system efficiency. Regular inspections and timely replacements can prevent costly breakdowns. Ensure your HVAC system runs smoothly by addressing these common issues. Proper maintenance extends the lifespan of your unit and keeps your home comfortable year-round.